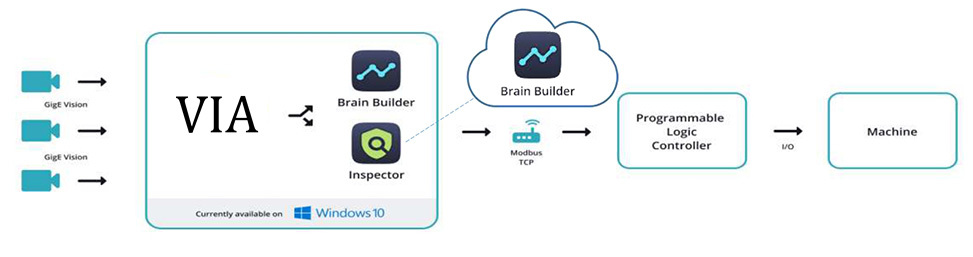

Vision Inspection Automation

Vision inspection automation is a process where computer vision technology is used to automatically inspect and analyse products or components in manufacturing and production environments. This technology utilizes cameras, sensors, and image processing algorithms to detect defects, deviations, or anomalies in real-time, ensuring the quality and consistency of manufactured goods. Here's an overview of vision inspection automation: